PROCESS CONTROL

SHORTER MAKE-READIES

BETTER PRINT QUALITY

MATCH ISO AND G7® PROOFS AND PRINTS

why do we need process control ?

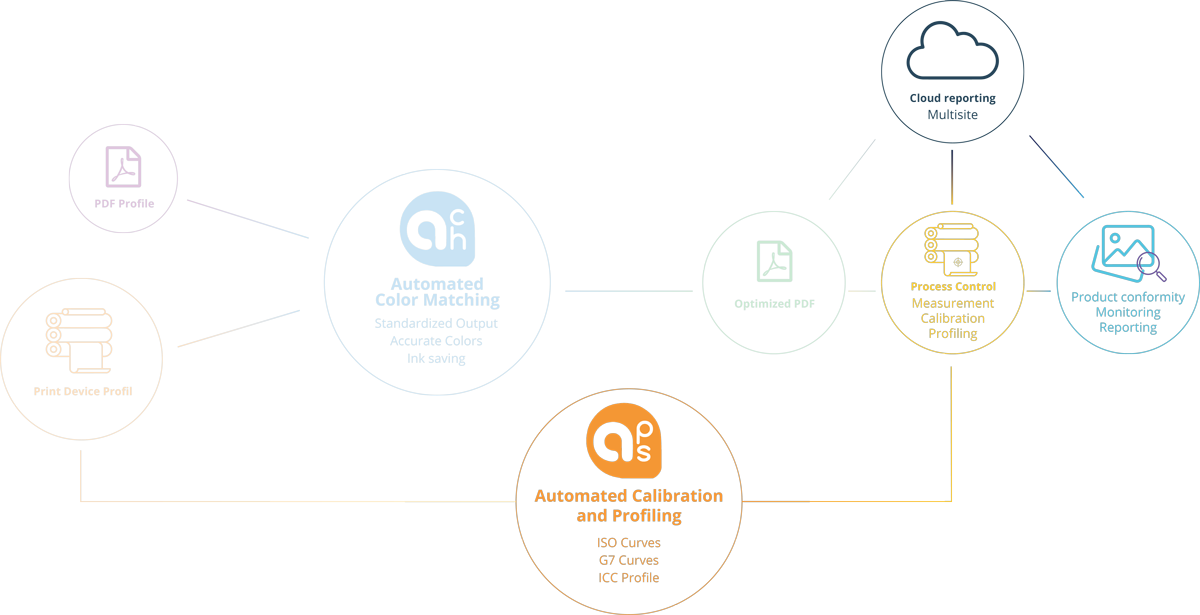

Printing Process solids and Tone Response Curves (TRC) should be controlled and adjusted in order to match intended printing conditions, standard or custom.

The printing press should be controlled in production and up-to-date adjustment curves should be applied on the CTP RIP regularly in order to obtain accurate, stable and reproducible colors.

what is process control ?

Process Control is the set of operations that allows you to define and monitor your print quality.

Conformance to ISO 12647 or G7®️ or in-house standards should be established.

Updated Adjustment curves should be made available to production RIP.

how does it work ?

HOW DO I IMPLEMENT process control?

Our process control server, Alwan PrintStandardizer, offers a unique, intelligent and automated calibration and profiling system that identifies, corrects, and maintains printer tone reproduction (dot gain) curves, gray balance and ICC profile, hence eliminating manual operations and human errors. Alwan PrintStandardiser web interface allows you to monitor your print production locally or remotely.

Ask for Trial Version